When we conduct stretch film packaging, it is generally used in conjunction with the stretch film. What is the working principle of stretch film? Generally, when packaging goods with stretch film, the goods should first be placed on the stretch film's

pallet. Then the machine starts to work, and the stretch film begins to rotate and wrap around the pallet. After the wrapping is completed, the two claws of the stretch film will automatically heat seal the two ends of the film, thus completing the packaging of a piece of goods.

When we use stretch film, we can appropriately understand its production process and principles to gain a deeper understanding during future use. So, what is the production process of stretch film?

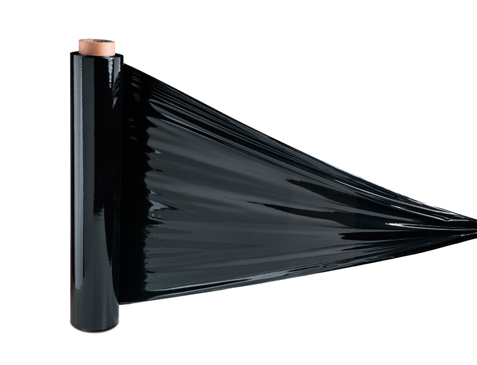

The earliest form of stretch film usage, from which more full-width packaging was developed. This kind of packaging requires the stretch film to be wide enough to cover the pallet. The pallet’s shape is regular, so its usage has a pattern, suitable for 17~35 microns thick manual packaging. This packaging is the simplest in packaging: the film is mounted on a rack or hand-held, and the pallet rotates or the stretch film wraps around the pallet. This product is mainly used for repackaging after pallet damage and general pallet packaging. The sealing speed is slow, suitable for thin films of 15~20 microns in thickness.

The stretch film blow molding extrusion system consists of a winding extruder, screen changer, die head, film bubble inner cooling, and air ring. As the output and quality requirements for stretch film blow molding continue to increase, a good extrusion system is needed. Among them, the components of the winding extrusion system are interconnected rather than isolated, which is key to achieving high yield and quality. The melt is filtered through the screen changer to ensure purification. The die head transforms the melt provided by the extruder into a uniform thickness film bubble parison. The air ring has the functions of film bubble blow molding and controlling the film bubble shape and cooling efficiency. The film bubble inner cooling device plays an important role in improving the cooling efficiency of the film bubble and exhausting waste gas within the film bubble.

However, stretch film was initially produced using PVC as the base material with DOA as the plasticizer that also served as a self-adhesive agent to produce PVC stretch film. Due to environmental issues, high cost (relatively higher density than PE, resulting in less packaging per unit area), and poor stretchability, PVC stretch film was gradually phased out when domestic production of PE stretch film began around 1994-1995. PE stretch film initially used EVA as a self-adhesive material, but it was costly and had an odor. Later, PIB and VLDPE were used as self-adhesive materials, with LLDPE as the main substrate, including C4, C6, C8, and metallocene PE (MPE).

Using imported linear polyethylene LLDPE resin and special adhesive additives in a formulated ratio, multifunctional stretch films can be produced, including hand-use, resistance-type machine-use, pre-stretch type machine-use, UV-resistant, anti-static, and rust-resistant films. They have the following advantages:

1. Using a double-layer co-extrusion device, the produced stretch film maximizes the characteristics of each type of polymer, achieving optimal transparency, tensile strength, and puncture resistance at the melting point.

2. It has good stretchability, good transparency, and uniform thickness.

3. It has good longitudinal elongation, good rebound, good transverse tear resistance, and excellent self-adhesive overlap.

4. It is made of environmentally friendly recyclable materials, odorless, non-toxic, and can directly package food.

5. It can be made into a product with single-sided tackiness.

This type of adhesive film reduces the noise generated during the stretching process, and reduces dust and sand during transportation and storage. Stretch wrap film has high tensile strength, high elongation, good flexibility, and high transparency. It can be widely used for the concentrated packaging of various goods. The stretch wrap film has a single-sided tackiness that can stretch and wrap the packaged items tightly, preventing them from scattering, getting damaged, or getting contaminated during transportation. Moreover, its high transparency makes it easy to identify contents and reduces delivery errors. It also facilitates containerized storage and transportation.